Chinese electric vehicle manufacturer Xpeng Motors has opened the doors to the Zhaoqing Intelligent Industrial Park, a 3,000-acre factory that boasts 264 industrial robots across five cutting- edge workshops. John Thornton investigates this remarkable facility, which could single a step-change in how next-generation passenger vehicles are manufactured…

Self-built and wholly owned by Chinese electric vehicle and and technology company Xpeng Motors, the Zhaoqing Xpeng Motors Intelligent Industrial Park is a highly impressive facility – and possibly the most highly impressive facility – and possibly the most highly automated manufacturing plant in the world today.

Located in Zhaqing, Guangdong Province, the facility spans a planned area of 3,000 acres – with 1,500 acres dedicated to vehicle production facilities. Following the foundation-laying in December 2017, the factory was built over a period of 15 months, with Phase 1 construction of 900 acres completed in September 2019.

Since then rigorous pre-production testing and small-scale trial production runs have verified the entire manufacturing process. On 19 May 2020, the plant received an official production license from China’s Ministry of Industry and Information Technology to manufacture its second production model, the Xpeng P7 super long-range electric sports sedan.

The approval accelerated production of the P7, ensuring customer deliveries scheduled for Q2 2020. And according to He Xiaopeng, chairman and CEO of Xpeng Motors, “the plant is an essential component of our vision to build a smart mobility ecosystem, from in-house R&D to smart manufacturing to customer services”.

Intelligent manufacturing

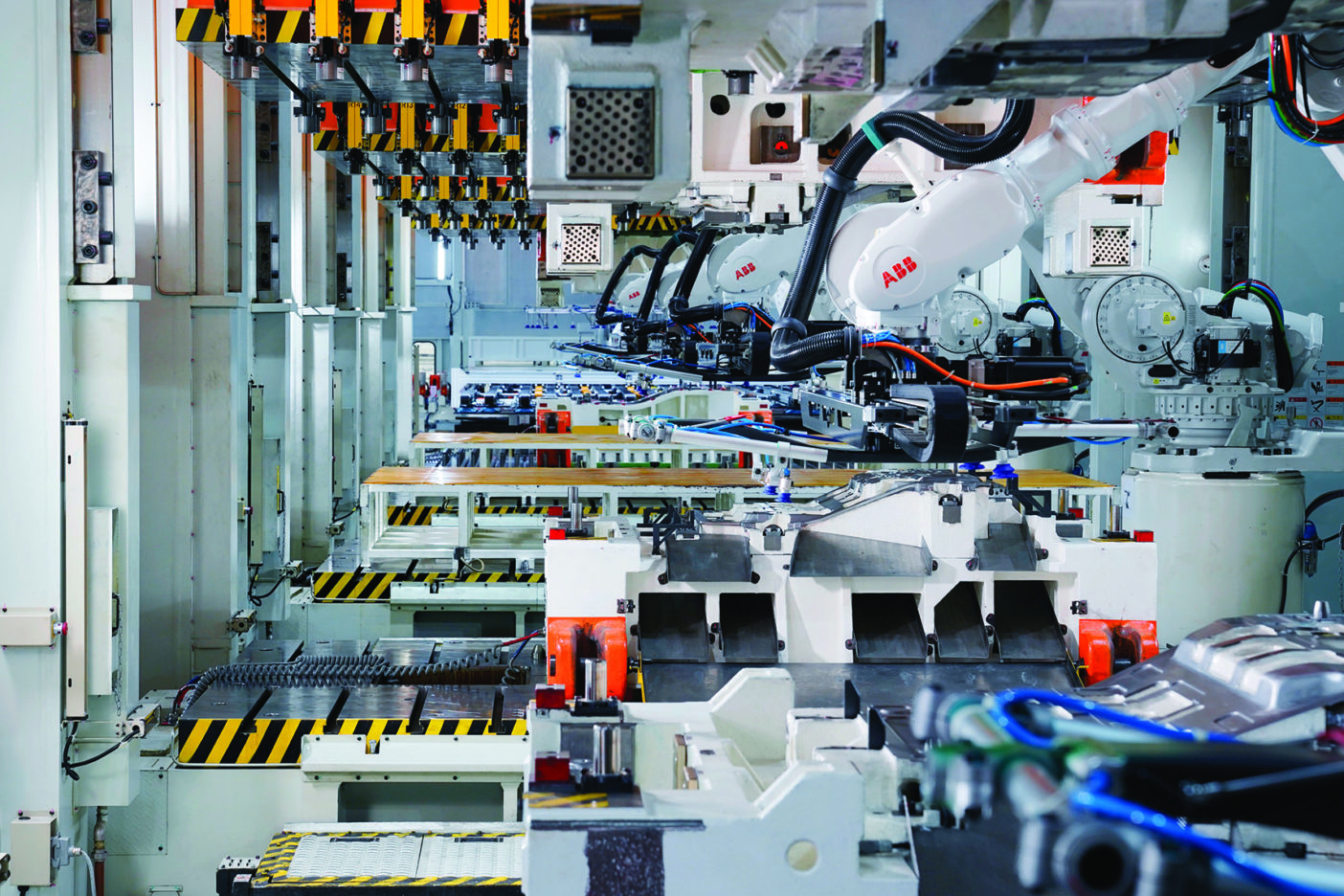

Though the facility is run by some 600 engineers, of whom 78% were headhunted by Xpeng from a raft of leading automotive OEMs, much of the vehicle manufacturing is undertaken by 264 intelligent industrial robots across five state-of-the-art stamping, welding, painting, assembly and battery pack production workshops.

The Zhaoqing plant has also been built in accordance with Industry 4.0 standards, with advanced manufacturing execution systems, Internet-of-Things technology, real-time production monitoring systems and a transparent manufacturing cycle.

“We are deeply proud of our achievement as a young company, in building our own wholly-owned smart manufacture base at Zhaoqing,” says Xiaopeng.

“Xpeng is now the only new smart electric vehicle maker in China that has both self-owned and contracted plants. We are a firm believer that manufacturing is the foundation of smart cars. Only when you build solid powertrain and vehicle hardware, can you differentiate with data operation, autonomous driving and connectivity software.

“This not only gives us optimal insight into and control over our production process, it also demonstrates our capabilities in successfully managing our supply chain and executing major projects. This is a great base for future development in intelligent vehicle design and manufacture.”

Indeed, it is. And it’s like nothing built before. Take, for example, the stamping workshop, which is fully automated. There, steel plates are stamped and formed on a 6,600-tonne large CNC automatic stamping production line, delivering as many as 12 pieces per minute. According to Xiaopeng, this is higher than the 10% industry average, with a precision range as narrow as 0.1mm.

“Equipped with an industry-leading information system, the production process is highly open and transparent, with real-time monitoring of processing parameters to ensure high quality consistency,” explains the CEO.

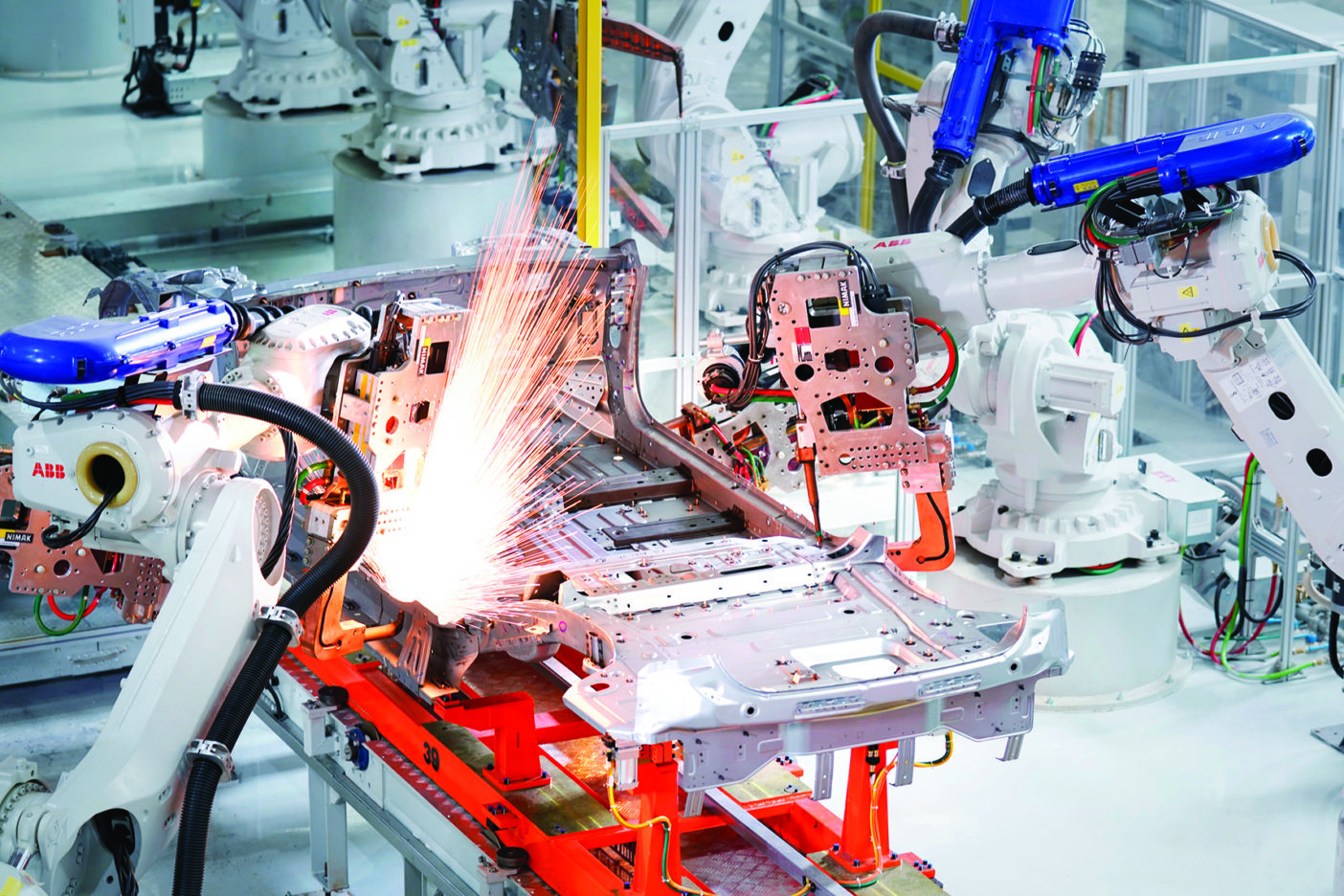

Bright Sparks

The welding workshop is equipped with 210 ABB industrial robots that meticulously perform multiple processes such as gluing, welding and aluminium plate riveting. Both Tier-1 and Tier-2 final assemblies reach a 100% automation rate, with the capability to manufacture steel-aluminium hybrid vehicle bodies.

What’s more, a self-adaptive medium frequency welding machine achieves a 30% energy saving, while the advanced visual gluing system reportedly yields gluing accuracy as fine as 0.5mm.

Over in the painting workshop, the Zhaoqing factory’s thin film pre-treatment and cathode electrophoretic technology effectively reduces wastewater discharge, while slag yield is also cut down by 94%, reducing energy consumption by 25%, and achieving zero emission of heavy metal pollutants.

The workshop also adopts BASF high-throwing-power coating material, with B1B2+2K water-based varnish double-layer painting technology, to significantly improve paint quality while also safeguarding the environment.

Quality control

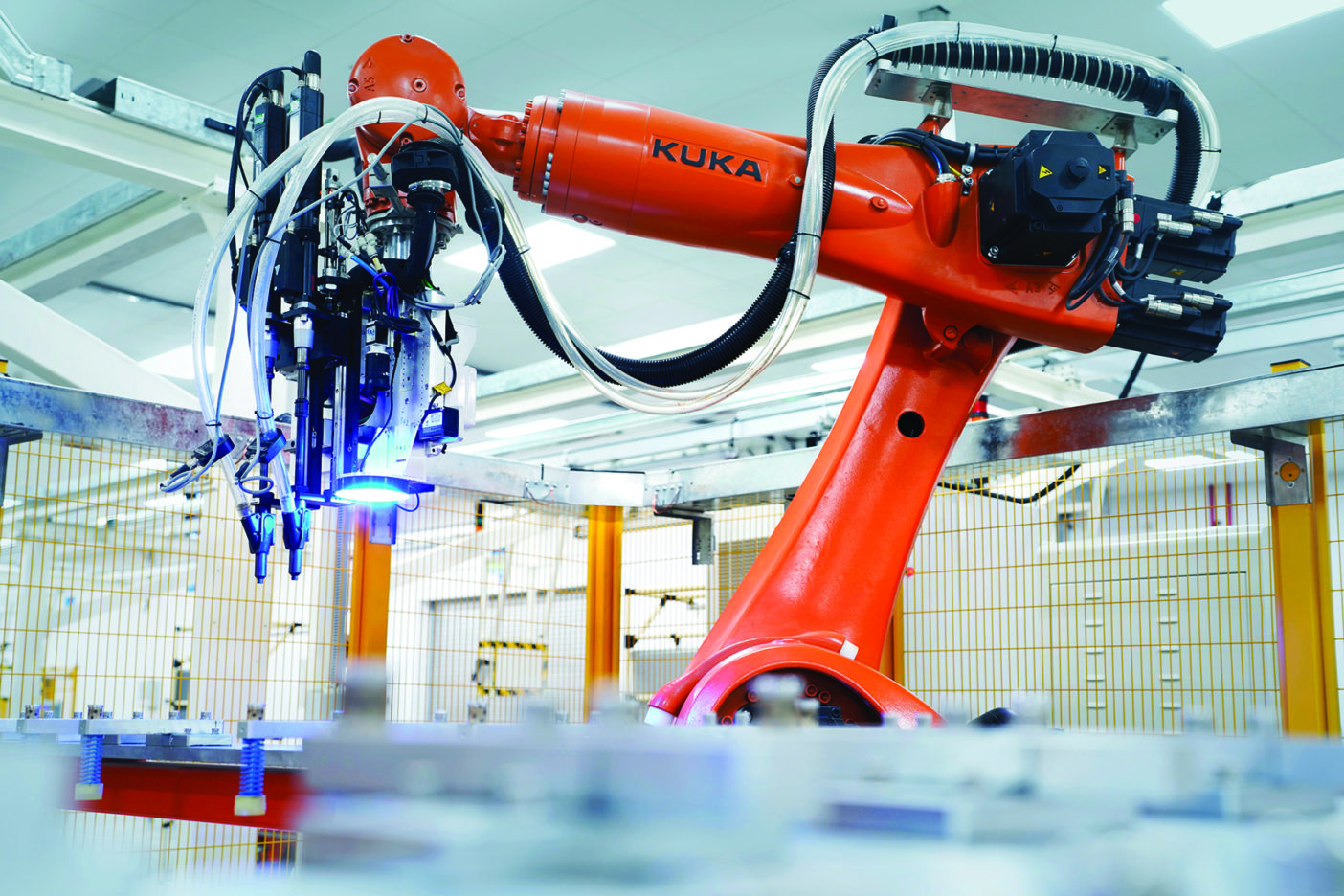

Robots also have the distinction of assembling Xpeng’s vehicles. Thanks to an automatic material supply and distribution system, AGV technology, automatic gluing robots and other assembly technology, all components are efficiently assembled. Furthermore, all key torque joints of the finished vehicles – known as CBUs, or Completely Built Ups – are tested online through a powerful digital production system to ensure quality control.

Finally, the battery pack workshop utilises an AGV-flexible production line, combining high-precision visual systems and robots to execute intelligent operations. An end-of-line test system conducts 198 offline tests and 89 battery performance tests for every battery pack. These include insulation, state-of-charge performance and BMS function to ensure that every pack meets IP68 sealing protection requirements.

By bringing manufacturing in-house, Xpeng Motors is aiming to enhance the autonomy, robustness, flexibility, cost-efficiency and intelligence of its vehicle production.

“The combination of end-to-end closed-loop R&D, smart manufacturing and quality customer services is our key differentiator. This facility marks another milestone in Xpeng’s six-year history, setting a solid foundation in pursuing our vision as a leader in the intelligent EV market,” Xiaopeng concluded.

Zhaoqing Xpeng Motors Intelligent Industrial Park – at a glance

Total planned area: 3,000 acres

Vehicle production facilities area: 1,500 acres Phase 1 construction: 900 acres Foundation-laying: December 2017 Construction completion: September 2019 MIIT production license: received on 19 May 2020 Industry 4.0 standards

5 workshops

600 employees

264 intelligent industrial robots

This article originally appeared in the July 2020 issue of Robotics & Innovation Magazine