Maria Highland presents five reasons why the logistics and manufacturing sector should be embracing digital twins…

Responding to changing conditions, identifying new opportunities and implementing new solutions across supply chains is never an easy feat – they are physically large, often span across the globe and have high throughput rates. Digital twins can lend a hand to achieving this without any disruptions or maintenance downtime. By creating digital replicas of the supply chain and its operations, businesses can gain full visibility of their operations to generate quality insights needed to drive innovation and respond to disruptions in real-time.

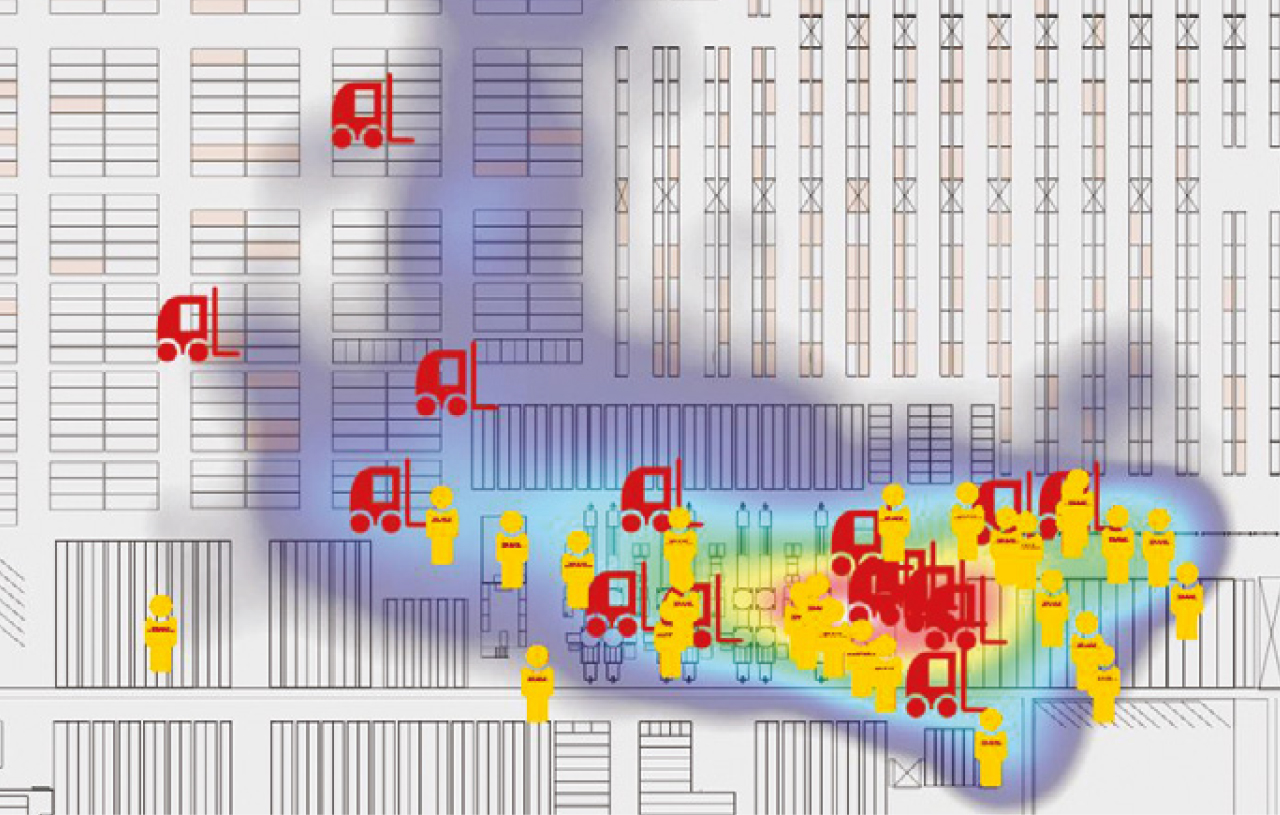

1 Create efficient warehouses

Digital twins are a great way of trialling new technology and assessing existing operations within a warehouse. Businesses can test whether technologies or certain layouts will improve warehouse operations without physically having to do it. By testing multiple scenarios, disruptions and maintenance time is greatly reduced.

“Digital twins are useful for logisticians and can bring deep insights into the way warehouses are planned, designed, operated, and optimised,” says Carl Green, chief technology officer Indigo Software, in his blog post ‘8 ways a digital twin can add value in the warehouse – using WMS data’. “By fine tuning the efficiency of a warehouse, businesses can make fractions of cost savings that when multiplied up, help ensure greater profit margins are secured.”

Likewise, Tomáš Vojtek, head of business and product strategy at Twinzo, points out that a digital twin is ideal for combining and visualising data from existing warehouse management systems with data from scanning systems that detect the location of items within a warehouse.

“A live digital twin serves as a hub to aggregate real-time data to compare information from a WMS about the position of material with sensorics input from that position,” says Vojtek. “When they don’t match, a digital twin can alert those responsible to fix the problem. The result is that the user knows the location of something in-real time. This can completely eradicate inventory counts in warehouses and increase utilisation of the space, plus decrease misplacement of packages.”

Digital twins also help to introduce robotics and automation by addressing what Vojtek believes is the biggest problem with autonomous mobile robot (AMR) deployment – rigid mission programming. “AMRs are able to deliver a mission from point A to point B but struggle in hybrid environments and dynamic positions in warehouses, where packages are moved frequently,” he says. “With a combination of spatial awareness, IoT sensor inputs and active f leet management, a digital twin can reroute AMRs to open positions in the event that the original position has been used by a human driver.

“Digital twins are the only way to enable both humans and machines to collaborate in real life, because only the digital twin is capable of holding all the data about warehouse premises from humans to machines,” Vojtek adds.

2 Refine transport logistics operations

By incorporating digital twins into logistics operations, businesses can achieve a more holistic overview of operations and ensure that everything run smoothy and efficiently, from truck to warehouse. As a result, operations benefit from time savings, accurate labour allocation for improved efficiency and cost savings. “Typically, warehouse optimisation is the primary vector for digital twin projects,” points out Körber in its whitepaper, ‘Discovering innovation with your digital twin’. However, some systems offer a wider view to include yard or transportation – which is beneficial when optimising upstream and downstream operations for tighter logistics overall.”

Correspondingly, Vojtek believes that that the “digital twin is perfect place to build applications for active management of logistic flow”. He explains that, “by using a digital twin and its applications, it’s possible o solve different problems that were before locked in silos. For instance, logistics fleet utilisation, which allows businesses to see whether routes are optimal or if yard layout is efficient.”

For example, combining an automatic ordering application with a digital twin “allows many systems to create an order,” says Vojtek. “If a truck comes to the gate, either the internal GPS system or presence sensor can detect its presence, and this can create an order to unload the truck for internal logistics f leets. “Whoever is available can accept this order and do the job,” he continues. “The same works for feeding the production line or loading a truck. This is fully autonomous management of logistics fleets through a digital twin. On top of that, 3D UI can be used to navigate drives around a facility to exact positions as needed.”

3 Inventory management

Building a virtual representation of a physical supply chain enables businesses to combine previously siloed data from disparate sources to achieve a complete overview of suppliers, inventories and other information. Such insights enable a more holistic approach to operations to drive end-to-end visibility.

A lack of visibility of operations often leads to retail stock outs, aging manufacturing inventory or weather-related disruptions. Likewise, Covid-related disruptions have underlined the need for real-time insights into operations, inventory levels and more.

“Siloed and incomplete data is limiting the visibility companies have into their supply chains,” explains Hans Thalbauer, managing director for global supply chain, logistics and transportation at Google. “A digital twin enables customers to gain deeper insights into their operations, helping them optimise supply chain functions – from sourcing and planning, to distribution and logistics.”

Google has recently released its own Supply Chain Twin solution, which can be integrated with various modules, such as Google’s Supply Chain Pulse, to provide real-time dashboards, advanced analytics and alerts on critical issues such as potential disruptions.

With Supply Chain Twin, companies can bring together data from multiple sources, such as locations, products, orders and inventory, from ERPs [enterprise resource planning] and other internal systems, to gain a better understanding of operations. Likewise, by integrating data from suppliers, such as stock and inventory levels, and partners, such as material transportation status, businesses can gain a more holistic overview of its operations.

French carmaker Renault has made use of Google’s digital twin solution to improve visibility of inventory levels across its network. Jean-François Salles, vice president of global supply chain at Renault, says: “By aggregating inventory data from our suppliers and leveraging Google Cloud’s strength in organising and orchestrating data, with solutions like the Supply Chain Twin we expect to achieve a holistic view. We aim to work with Google tools to manage stock, improve forecasting and eventually optimise our fulfilment.”

4 Achieve sustainability goals

In a post summarising his “Strategic Thinking” keynote at the buildingSMART virtual summit on 17 March 2021, Bart Brink, global director for digital twin at independent engineering and project management consultancy Royal HaskoningDHV, explained that digital twins can play a fundamental role in the future of sustainability.

There are two key ways digital twins can drive sustainability, according to Brink. First, the aspect of digital twins that helps to capture, organise and display data to give a realistic model of the physical world can be used “to understand and quantify what’s happening, and combine multiple data sources to see the impact of decisions we’ve made,” he explains. Secondly, “the digital model can be used as a predictive guide to the future. This can show what’s likely to happen in future, compare possible scenarios and forecast the outcome of different decisions before they’re taken,” he continues.

As well as asset management, the dynamic nature of the modelling lends itself to other areas, such as logistics optimisation, points out Brink. “Importantly for sustainability, twinning can also help to predict water network f low, balance energy grids and build resilience in the face of the impacts of climate change.” However, “to maximise the benefits, digital twins need to be elevated from focusing on individual assets only, to encompass whole processes or even entire enterprises,” warns Brink.

Luckily, as digital twins operate by bridging data silos and unifying access to data through 3D models, analytics of system dependencies become much easier, according to Vojtek. This is particularly useful when looking to drive sustainability across operations because it helps businesses determine how different departments interact and the relationship between them. For example, businesses will be able to see if one department is negatively impacting another and why, which results in consistent data-driven self-improvement – including tackling sustainability goals.

5 Navigate disruption appropriately

Having a digital version of operations allows businesses to test out various scenarios and technologies to see how they fare without having to invest big bucks in infrastructure and technology. “The benefits of this ability to ‘try things out’ are multi-faceted,” says Harry Watts, managing director at SEC Storage Group. “For example, organisations may test how proactive changes to a process would impact the efficiency of their operation, or how resilient an operation would be if it were to handle a possible adverse event, such as supply-chain disruption or a sudden labour shortage.”

Likewise, “a comprehensive understanding of the potential implications may have substantial positive financial and customer service implications,” he adds. This is particularly useful during disruptions as multiple scenarios can be quickly tested to ensure the best action is taken.

“When you add in the real-time statistical feedback commonly associated with digital twinning, you gain vital operational data that can be analysed in real-time to help identify and mitigate against risks in advance or recognise opportunities for operational improvement,” explains Watts.

“And, in the modern logistics environment, fraught with significant risks of supply-chain, geopolitical, environmental and other forms of disruption, the digital twin actually becomes a platform for operational agility since the real-time information and repetitious scenario modelling inform proactive decision-making, that allows us to transition away from the traditional view of hard assets as being fixed and instead see them as flexible.”

SEC worked with Focus International (part of JD Group), which faced uncertainty about how Brexit would affect its operations. “Our digital-twin driven solution facilitated an almost 100% increase in pick-rates, a 40% increase in overall capacity and enabled Focus to handle a nearly 300% increase in turnover across just two years – as well as markedly increasing the ability of the organisation to plan for and adapt to an unknown Brexit outcome,” says Watts.