Perceiving robotics and AI as an integral part of the decommissioning of nuclear sites will improve the safety and efficiency for those involved in hazardous work, writes Rav Chunilal, head of robotics and artificial intelligence at Sellafield…

The Sellafield site in West Cumbria has led the development of the UK’s nuclear industry for 70 years, from the production of plutonium for the country’s nuclear deterrent programme through to the development of nuclear power generation.

Today it is facing up to the challenge of cleaning-up its legacy – the ponds and silos full of waste created by the site’s early operations, including some of the most hazardous nuclear facilities in Europe. And robots are expected to be at the forefront of delivering this.

There are many reasons – robots can operate safely in hazardous conditions, they can fit where no human ever could, and they can perform tasks in hard-to-reach areas quickly and simply. All of which are vital to achieving Sellafield’s eventual goal of creating a clean and safe environment for future generations.

Robots have been used on and around the Sellafield site for decades. But as the technology has improved and the concept of artificial intelligence (AI) has been introduced and perfected, their potential to help and improve the delivery of the Sellafield mission has been recognised.

Robotics and AI is being embraced across the NDA Group led by Sellafield. It has recently set up a central robotics and AI capability supported by four domains: air, land, water robotics, and AI centres of excellence. Each of these domains are being managed across Sellafield within our remediation and retrievals value streams, as well as engineering and maintenance, technology groups and integrated research teams.

And it is the job of the organisation’s robotics and AI capability to identify these opportunities and ensure that the organisation collaboratively takes full advantage of what robotics can offer across the Sellafield site and the NDA Group.

Robotics and AI are fundamental in delivering Sellafield’s number one priority – safety – by keeping people out of harm’s way. Using Robotics and AI effectively can have a positive impact on both nuclear and conventional safety. They can be used to perform repetitive, difficult and time-consuming jobs remotely – freeing up our people to take on roles that are more fulfilling and rewarding, ultimately helping deliver our organisations purpose. We will focus on the long-term uses of these technologies as they continue to develop and evolve.

The use of robots has already proven they can keep our people safe – but there is still potential for them to help speed up the mission, making Sellafield safer, sooner – whilst also contributing towards delivering some of the NDA’s grand challenges. It’s a compelling vision and shows how Sellafield’s 70-year legacy was tailor-made for today’s technology.

In water, we need our robots to scour our ponds, pick up and cut material and then sort the nuclear inventory sitting underneath the surface. We’re currently developing ‘tetherless’ underwater robots with basic AI, which can move around our ponds with minimal human intervention – and without the usual heavy umbilical connection that can get caught and impede operations.

On land, we require robots that can be lowered into hard-to-reach areas such as the silos and compartments we use to store waste, and then operate in what can be extremely toxic environments for significant periods of time. Initiatives such as the Innovate UK Integrated Innovation for Nuclear Decommissioning competitions are developing capabilities to allow waste to be remotely characterised, dismantled and decommission cells in-situ. The recently launched Long Arm Operations (LongOps) programme will be a collaborative step forward with NDA, RACE (UKAEA) and Tepco in undertaking remote decommissioning at Sellafield.

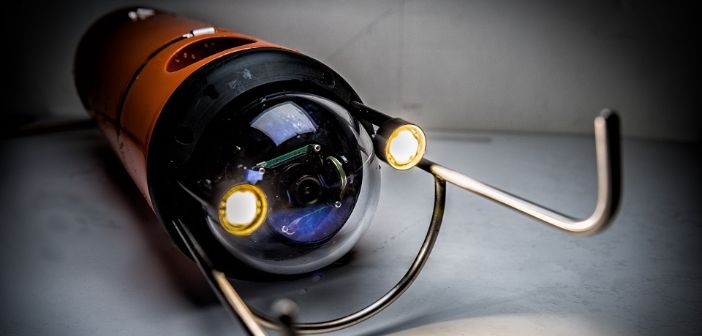

Our robotics and AI capability continues to work with our partners and colleagues in the national nuclear laboratory, academia and the supply chain to develop solutions. Recently, the newly developed remote operated vehicle (ROV) had to negotiate a 30m vertical drop before travelling through a 20m inspection route around obstacles, all this whilst in a gamma radiation field 10 times the highest radiation levels usually found in our hot cells.

The ROV they built – with extra tough components and extra radiation shielding – has now been successfully tested, giving us a better understanding of the store condition, and evidence we can use to plan future stores. It is also fully reusable and can be sent back in to check on possible degradation over time.

And in the air, we have identified drones that can carry out detailed infrastructure inspections quickly and safely, at a reduced cost. The inclusion of AI means that they can operate independently and spot degradation much sooner. The UAV team at Sellafield has been at the forefront of developing and trialling flights beyond visual line of sight in the UK with sees.ai and the Civil Aviation Authority.

With robots being such a fundamental part of our future, and new opportunities for their use being identified all the time, the robotics and AI capability has set up a new facility in nearby Whitehaven. It is a space led by Sellafield with the UK Atomic Energy Authority’s Remote Applications in Challenging Environments programme, RACE, the National Nuclear Laboratory, NNL and University of Manchester.

The robotics facility in Whitehaven will enable us to collaborate with our partners and supply-chain on innovation and applied R&D in solving real challenges. It will bring together the work being done by robots across Sellafield and build on the opportunities they offer under one roof. This will be the steppingstone to realising greater benefits for a much larger robotics and AI collaborative space in West Cumbria.