Construction of a new terminal at Denver International Airport is being aided by the deployment of a dog-like robot platform, integrated with construction management software solutions, GNSS technology and reality capture devices, to autonomously scan and survey areas of the project site.

Performing construction work in an operating airport is a complex and challenging project. Doing so in one of the busiest airports in the world is even more demanding and requires an experienced team and innovative approach. The massive renovation project of Denver International Airport’s (DEN) Great Hall terminal falls under this category.

The DEN Great Hall project is a multiple phase project focusing on increasing open space within the airport, improving the customer experience, and enabling safer and intuitive passenger flow. The current phase of the project focuses on the centre of the terminal with new ticketing pods and checked baggage systems.

To handle the complex logistics and the challenges in this demanding project, DEN selected Hensel Phelps as the general contractor and construction management partner.

Pre-planning process

According to Drew Rebman, a virtual design and construction engineer at Hensel Phelps, a key aspect for success in such projects is a thorough pre-planning process.

“This process helps reveal undocumented assets, resolve potential safety issues, identify deviations from existing as-built documents, and solve discrepancies between the site conditions and the design,” explains Rebman.

Hensel Phelps uses laser scanners throughout construction projects for quality and production control purposes. During pre-planning, the scanners are used to capture the details of the existing structure, a method that the company says provides rich and highly accurate output and eliminates the labour-intensive manual measurement process.

The challenge

Multiple scans are needed to capture the as-built conditions of a project such as the DEN terminal area. The scanner operator is required to carry the optical equipment and a tripod from one point to the other and wait at each point for the scan to be completed.

A full set of scans can take several hours, or even days, to complete. During this time, the operator is required to be nearby, exposed to the complex workspace environment.

A solution that enables remote operation, frees on-site workers from repetitive work, and allows the team to focus on more demanding tasks can help overcome the current workflow limitations.

The solution

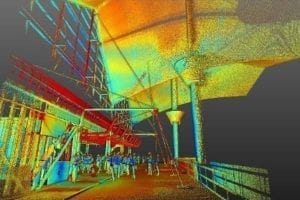

To further improve data collection efficiency and the safety of the on-site team, Hensel Phelps decided to explore the integration of robots in the scanning workflow. A Boston Dynamic’s Spot robot with an integrated Trimble X7 scanner was deployed on the project, performing scans, and capturing 360 images of the site.

Spot is a quadruped robot with spatial perception. It can carry up to 30 lb of payload and is designed to manoeuvre in unstructured and dynamic environments such as construction sites. Trimble X7 is a compact, high-speed 3D laser scanner.

The X7 produces point clouds with up to 2mm scanning accuracy and high-resolution panoramic images. Its auto-calibration, self-levelling, and automatic in-field registration capabilities enable an autonomous scanning workflow.

The workflow

The integration of Spot with Trimble X7 was done through Trimble software on top of Boston Dynamics’ software development kit. The software gets information from Spot’s mission system and initiates a scan at pre-defined waypoints.

There are two basic working modes. The first one is an ad-hoc mode in which the user remotely controls Spot, navigates the robot to the required location and triggers a scan.

The second mode is autonomous and is based on a planned mission with waypoints in which the Trimble X7 performs scans. With the latter mode, the integrated solution follows a pre-defined path and performs scans autonomously.

The Hensel Phelps team utilised both manual and autonomous modes at the DEN terminal. The output point cloud files were automatically transmitted to a Trimble T10 tablet via the X7 local wi-fi and auto-registered in the field using Trimble Field Link software.

This process helped verify that the entire space had been captured, reducing the risk of return visits – an especially important capability in this type of projects where access permits and logistics can cause delays. The captured as-built information was compared to a BIM model of the design to eliminate surprises and delays during construction.

Into the future

The Hensel Phelps team believes that robots will be part of the future workforce, working side-by-side with humans and performing dull, repetitive, and dangerous tasks.

“The potential benefits of in-field robotics are huge, and the partnership between Trimble and Boston Dynamics is exciting news,” says Jeremy Sibert, director of technology at Hensel Phelps.

“Robots can help improve productivity, quality, and most importantly the safety of our on-site teams. It is an exciting journey and we are looking forward to further integration of autonomous robots in construction workflows.”